Mill with Confidence and Ease

The DWX-4 Compact Dental Mill is designed for simple operation so that users can quickly set-up and start creating precision prosthetics right out-of-the-box. It combines simultaneous 4-axis milling with simple one-button operation and offers intuitive features such as a color-coded LED light that signals machine status and an automated tool changer which provides two tools for precision unattended milling from start to finish.

Powerful Production Capabilities

The DWX-4 includes an automatic tool changer for two tools, and can be enhanced with the addition of an optional 4-position automatic tool changer which supports up to four different tool sizes.

With an optional multi-pin clamp, the DWX-4W can mill up to four prosthetics in a single production run. The additional multi-pin clamp mills different pin-type materials simultaneously and saves time, labor and costs.

Compatible with Multiple Materials

The DWX-4 Compact Dental Mill is equipped to mill standard blocks and pin-type materials, including wax, PMMA, zirconia, hybrid ceramic, and resins. Hybrid ceramics and resins, such as VITA ENAMIC® and 3M™ ESPE™ Lava™ Ultimate Restorative are acclaimed in the industry for their superior strength and aesthetics. They can be finished without firing, which dramatically reduces labor and production time.

Connect Multiple Machines

Highly scalable, the DWX-4 offers multicast capability that allows you to connect up to four Roland machines to one computer, making it easier than ever for dental labs to expand their businesses and increase production capacity. The DWX-4 Compact Dental Mill lets labs control the entire process in-house with a single software seat, maximizing your investment and resources.

Virtual Machine Panel

A user-friendly Virtual Machine Panel (VPanel) provides advanced controls so users can operate all machine diagnostics, calibration and milling processes from a desktop. The VPanel also tracks spindle time, tool and collet time, and overall machine time for maintenance.

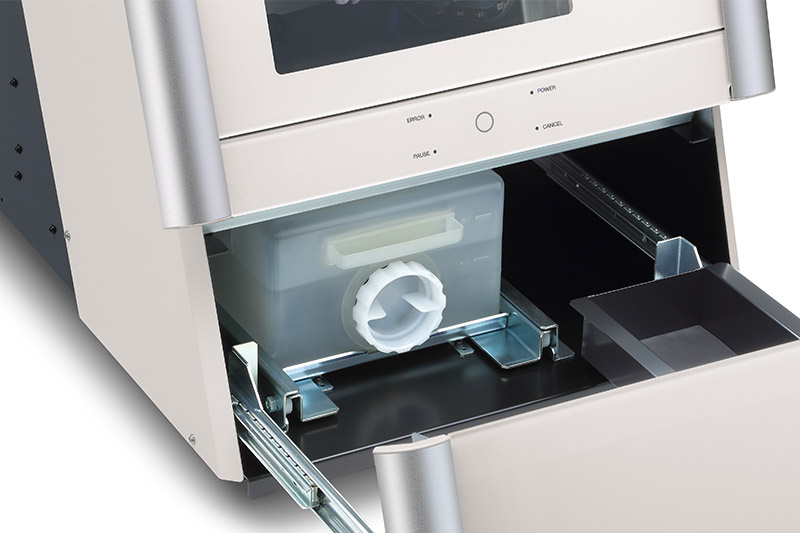

Clean Milling Area

An integrated air blower prevents excessive dust buildup, while a negative ion generator reduces static electricity when milling PMMA. A dust collection sensor prevents the machine from starting if the vacuum is inadvertently left off.

Economical Open Architecture

The DWX-4 comes with EasyShape CAM software that’s compatible with STL file types. The open architecture of the DWX-4 enables production with the latest materials, CAD/CAM software and scanners so you're not limited to the technology you can use. If you already have a production solution, the DWX-4 works perfectly with your existing scanner and compatible CAD/CAM software and eliminates reliance on a single source for materials. Compatible with RML-1 and NC code, the DWX-4 interfaces with your computer through a USB connector.

EasyShape CAM Software Included

EasyShape CAM software is bundled with the DWX-4 and supports all STL files for milling a range of prosthetics and materials. It provides a user-friendly interface and simplified workflow to ensure a fast learning curve. Other features include automatic nesting and placement options to maximize efficiency and pre-defined milling procedures for direct software-to-mill functionality without interruption during tool path calculation.

| DWX-4 Milling Machine | |

|---|---|

| Cuttable material | Zirconia (pre-sintered), Wax, PMMA, Lava™ Ultimate Restorative |

| Loadable workpiece shape | Block: Width x Depth: 76×38, Height: 10 to 22 mm PIN type: Width x Depth x Height: Maximum 85 x 40 x 22 mm |

| Operating speed | XYZ axis: 0.24 to 70.8 in./min. (6 to 1800 mm/min.) |

| Spindle motor | Brushless DC motor |

| Spindle speed | 6,000 to 30,000 rpm |

| Rotary axis travel angle | A: ±360° |

| Number of burs housed | 2 |

| Attachable too | Shank diameter: 4 mm, Length: 40 to 55 mm |

| Compatible compressed air | 0.02 to 0.2 MPa |

| Interface | USB (compliant with Universal Serial Bus Specification Revision 1.1) |

| Control command set | RML-1, NC code |

| Power requirements | AC100 to 120 V/220 to 240 V ±10 %, 50/60 Hz (overvoltage category II, IEC 60664-1) |

| Power consumption | Approx. 70 W |

| External dimensions | Width x Depth x Height: 13.4×14.4×16.0 in. (340×365×405 mm) |

| Weight | 48.5 lbs (22 kg) |