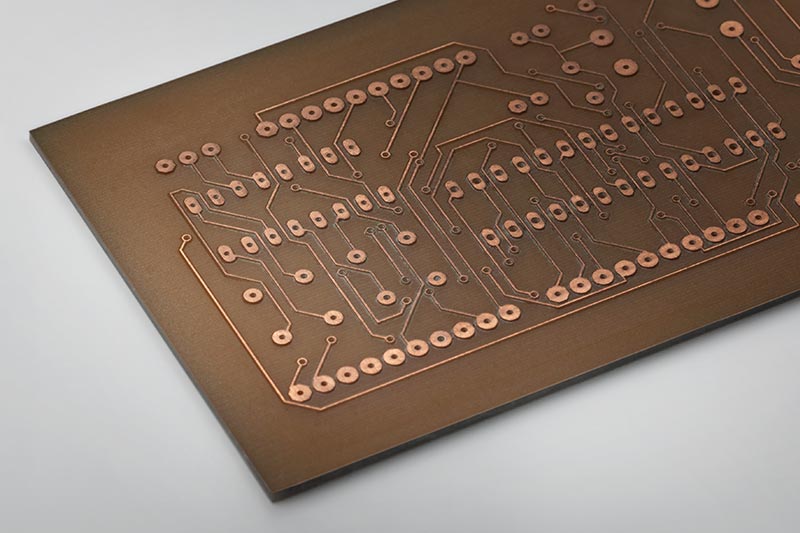

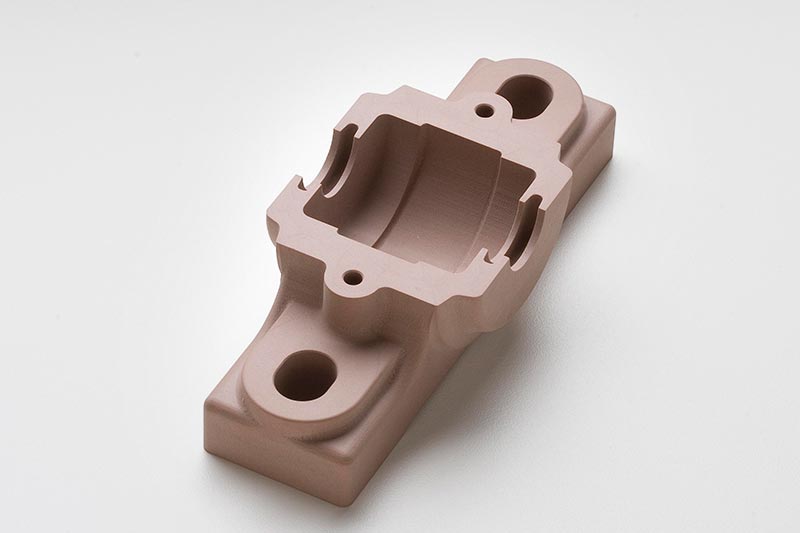

Create Realistic Prototypes

A wide range of materials, including modeling wax, chemical wood, foam, acrylic, poly acetate, ABS and PC board can be precision milled using the SRM-20 small milling machine, allowing you to create realistic 3D prototypes that are virtually identical to production parts.

Precision and Productivity

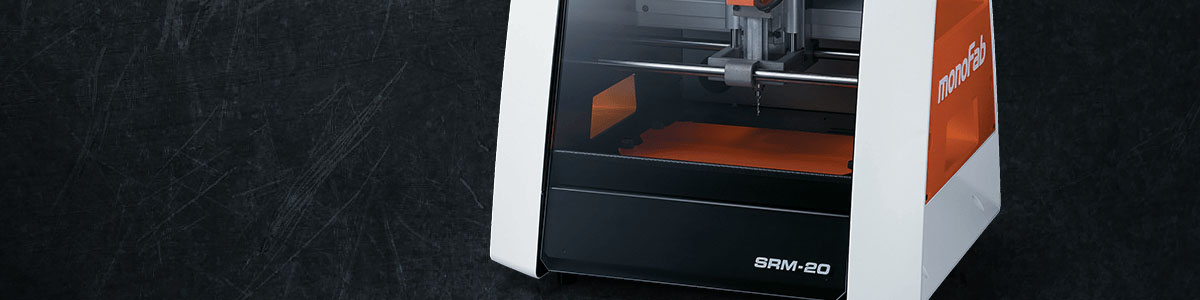

Engineered for optimum efficiency and productivity, the SRM-20 is a next-generation desktop mill that boasts a micro-step motor drive system for clean and precise contours and a phenomenal feed rate that’s two times faster than previous generations.

Multi-axis milling is as easy as X, Y and Z

The SRM-20 was designed with a number of technological advancements that include a touch-button VPanel controller to regulate feed rate, spindle speed and milling on a complete X, Y, Z axes, and a new independent collet system that allows for faster setting of the Z-axis base point and quick tool changes.

| SRM-20 | |

|---|---|

| Cuttable Material | Modeling Wax, Chemical Wood, Foam, Acrylic, Poly acetate, ABS, PC board |

| X, Y, and Z Operation Strokes | 8 (X) x 6 (Y) x 2.38 (Z) inches, 203.2 (X) x 152.4 (Y) x 60.5 (Z) mm |

| Workpiece table size | 9.14 (X) x 6.17 (Y) inches, 232.2 (X) x 156.6 (Y) mm |

| Distance From Collet Tip to Table | Maximum, 5.15 in (130.75mm) |

| Loadable workpiece weight | 4.4 lbs (2kg) |

| XYZ-axis motor | Stepping motor |

| Operating Speed | 0.24 – 70.87inch/min, 6 – 1800mm/min |

| Software resolution | 0.000039 inches/step (RML-1), 0.000039 inches/step (NC code) 0.01 mm/step (RML-1), 0.001mm/step (NC code) |

| Mechanical resolution | 0.0000393 inches/step, 0.000998594 mm/step |

| Spindle motor | DC motor Type 380 |

| Spindle rotation speed | Adjustable 3,000 – 7,000 rpm |

| Cutting Tool Chuck | Collet method |

| Interface | USB |

| Control Command Sets | RML-1, NC code |

| Power Requirements | Machine: DC24V, 2.5A, Dedicated AC adapter: AC 100-240V ±10%, 50/60Hz |

| Power Consumption | Approx. 50W |

| Operating Noise | During operation: 65 dB (A) or less (when not cutting), during standby: 45 dB (A) or less |

| External Dimensions | 17.76 (W) x 16.80 (D) x 16.78 (H) inches, 451.0 (W) x 426.6 (D) x 426.2 (H) mm |

| Weight | 43.2 lbs, 19.6 kg |

| Installation Environment | Temperature of 41 to 104 °F (5 to 40°C), 35 to 80% relative humidity (no condensation) |

| Included Items | USB cable, AC adapter, Power cord, Cutting tool, Collet, Set screw, Spanners (7,10mm / 0.28, 0.39 inches), Hexagonal wrench (size 2,3 mm / 0.059, 0.12 inches), Positioning pins, Double-sided tape, Start-up page guidance card |